The machine for the pellet production is the top choice for the production of pellets from waste wood such as dry sawdust, shell walnuts, hazelnuts, almonds, with automatic feeding and funnel for independent work of 30 minutes. Suitable for work pellets of dry sawdust, waste wood chips, biomass, olive cake, shells of nuts, grains waste mixed with wood shavings, pitted peaches and apricots, chopped cardboard, shell chestnuts. It is used for the production of pellets of fertilizer and manure-made from poultry manure and dried animal dung. For the production of pellets to feed hay, alfalfa, wheat, corn cobs mixed with flour of wheat.

Specifications: Engine Machine Pellet 4KW or 5.5 kW or 7 kW) engine with gearbox and agitator speed variator 5-20 of 0.22 kW. All motors three phase 380 V.

Diameter of toothed rollers 75 mm, heat treated, 500 hours included.

Production capacity of 30-40 kg / hour

Weight: 221 kg, dimensions 68x68x190 cm.

The machine is supplied with and without dispensers. When the machine without dispensers need to constantly pour a little mix pelleting, and the dispenser of the greater amount of success and he dosed the next half hour.

For higher capacity are available types of double machine.

It can be supplied with the drive shaft drive tractor. Tractor must have min.20KS force on the transmission shaft.

You can add dispenser.

MILL CRUSHER FOR PREPARATION OF MATERIALS WOOD

The raw material for refining wood chips or shavings of wood. With replacement screens mounted on the outlet of the filter can be obtained particle size of the product 3 mm.

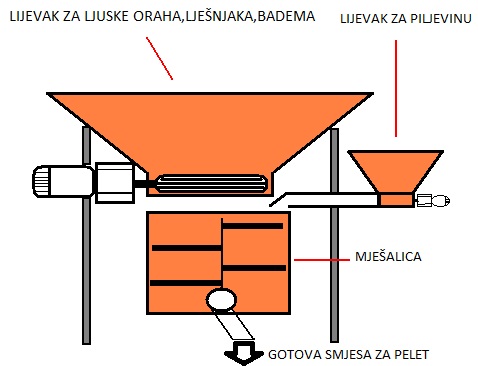

In the case that it is desired to use walnut shell, hazelnut, almonds, which are of high hardness and without moisture, it is necessary to grind the raw material finely in special grinder, and mixed with a minimum 10% sawdust.

Special offers the possibility of grinding and mixing in the adjustable desired ratio with sawdust. This gives us optimal caloric power pellets.

Line for pellet