Hand crusher 50-1M

Hand crusher 50-1M

Used by customers for small production needs

• fresh or roasted hazelnuts and almonds, walnuts, peanuts, roasted walnuts in general, chestnuts

• chocolates

• crumbly nougat and crunchy

• biscuits, meringues and similar products

Hourly production is 10-15 kg / h, depending on the type of product used.

Grain size can vary from 3 to 6 mm depending on the selected setting.

A pair of adjustable AISI 304 stainless steel rollers have a setting that allows good flexibility in machining with a length of 50 mm with 3.5 mm teeth (step 7 mm)

The rollers are also equipped with special stainless steel scrapers, for self-cleaning during the grinding process

The grinding machine has the property of not kneading the product, thus leaving the properties unchanged and preventing it from burning.

The use of serrated rollers ensures that the dried fruit does not lose oil, and thus the aroma and taste remain intact.

Settings:

– The grain size is obtained by changing the distance of the rollers acting on the handwheel.

– It is possible to order other pairs of rollers with different steps, easily interchangeable on machines, to obtain different types of pieces.

Overall dimensions: 450 x 450 x 600 mm. Weight: 30 kg

AUTOMATIC CRUSHERS

Crusher for roasted nuts (hazelnuts, peanuts, walnuts, almonds, etc.), nougat, crunchy, biscuits and chocolate.

Crusher for roasted nuts (hazelnuts, peanuts, walnuts, almonds, etc.), nougat, crunchy, biscuits and chocolate.

The machine consists of a module of rotating knives for the production of different sizes of grain or powder, and is characterized by rapid interchangeability and ease of cleaning.

Depending on the type of production, we are able to offer different models with a production of 70-600 kg / h depending on the grain size.

We can offer crushers several cutting steps of 2 steps (for grain), 3 steps to 4 steps for crumbs and powder (particle size less than 1 mm).

Crusher model 100-2T

This machine is used for the production of grain according to the customer’s request and based on the cutting rollers used (The rollers must be defined in order confirmation and against signed by both parties)

The grinder machine model CRICK-CROCK is particularly suited for the processing:

– Dried fruits (hazelnuts, toasted almonds or fresh walnuts, peanuts, chestnuts etc.).

– Chocolate in bars

– Crumbly nougat

– Crispy

– Biscuits, meringues and similar products

Production capacity:

80-110 Kg/h variable according to the type of product and the desired particle size

Machine dimensions:

Width: 600 mm, Length: 900 mm, Height including the hopper: 1700 mm

Weight with frame: 150 kg

Electrical connection:

Connecting to the grid with 5-pin socket 16 ° (3 phases + neutral + ground) with voltage 400V, frequency 50 Hz

Power supply required: 0,37 kW

Different types of electrical connections (voltage and frequency) must be specified by the customer BEFORE confirming the order

Features rollers:

The grinder machine model CRICK CROCK-100-2T uses TWO pairs of rollers, adjustable, in stainless steel, 100 mm length.

– First pair with tooth 6 mm (step 12 mm)

– Second pair with tooth 3 mm (step 6 mm)

All the rollers are provided with special scrapers, in AISI 304 stainless steel used for cleaning the teeth and holes during the production

Technological properties:

The grinder machine CRICK-CROCK: has the property of not crush the product, thus leaving unchanged the properties and preventing rancidity of the product.

The use of toothed rollers allows the dried fruit of not losing the oil and, consequently, the aromas and flavour remain intact.

settings:

– The size of the grain is obtained by acting on the graduated wheels to increase / decrease the distance between the rollers.

– It is possible to order other pairs of rollers with different steps, easily interchangeable on the machinery, so as to obtain different types of crops.

Technical description:

– The machine is completely made of stainless steel AISI 304.

– Frame in stainless steel AISI 304 on wheels to easily move the machine

– Hopper in stainless steel AISI 304

-Inverter for adjusting the rotation speed of the cutting rollers.

CRUSHER model 100-3T

Production capacity:

70-110 Kg/h variable according to the type of product and the desired particle size

Machine dimensions: Width: 600 mm, Length: 900 mm, Height including the hopper: 1700 mm, Weight with frame:190 kg

Electrical connection:

Connecting to the grid with 5-pin socket 16 ° (3 phases + neutral + ground) with voltage 400V, frequency 50 Hz

Power supply required: 0.75 kW

Inverter for adjusting the rotation speed of the cutting rollers.

CRUSHER model 100-4T

Production capacity: 70-110 Kg/h variable according to the type of product and the desired particle size

Machine dimensions:Width: 600 mm Length: 900 mm Height including the hopper: 1700 mm Weight with frame:190 kg

Electrical connection:

Connecting to the grid with 5-pin socket 16 ° (3 phases + neutral + ground) with voltage 400V, frequency 50 Hz Power supply required: 0.75 kW

LARGE CAPACITY CRUSHERS

CIRCULA VIBRATING SIEVE model 600

CIRCULA VIBRATING SIEVE model 600

This equipment is used to divide different grains sizes from nuts, chocolate, hard candies, toffee, or other hard products normally coming out from the grinder mach 70-110 Kg/h depending on the grain size required.

This circular vibrating sieve is including:

– First mesh in stainless steel AISI 304 grain dimension 6 mm, wire d=1 mm

– Second mesh in stainless steel AISI 304 grain dimension 3 mm, wire d=1 mm

– Transparent silicone gaskets suitable for food applications

– Topper round out feed Ø 160mm

– Inclined plane round out feed Ø 200 mm

– Mechanical parts in contact with food in stainless steel AISI 304

– Central band with two fins and a conveying help unloading, opening portholes for inspection, round out feed Ø 160mm

– Vibrating unit with motor 1400 rpm 50/60 Hz

– Frame in painted iron (stainless steel is an additional option)

Meshes cleaning system with hard stainless steel support and. 250 rubber balls for food, mounted only on the lower mesh

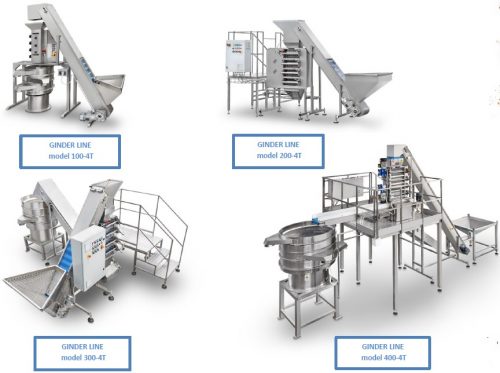

AUTOMATIC CRUSHER LINE WITH SITES

They are made in different capacities of 100, 200, 300, 400, 500, 600 kg / hour or according to the customer’s request. The crusher automatically crushes the product, which separates on sieves to the desired granulation.