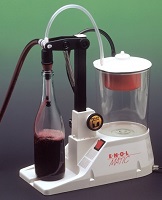

Enomaster and Enolmatic Enomaster and Enolmatic filling machines operate like vacuum filler. It is the ideal equipment for edible juice and oil producers, cellars, wine-producers and distilleries. The ideal equipment for filling wine, oil, spirits, liquor, tomato sauce, fruit juices, and also liquids with relatively high viscosity. Through vacuum operated filling, the product is bottled in the most natural way, allowing to maintain the product original qualities and features. When placing the bottle under the machine, the fluid is drawn by the vacuum created inside the container itself, without any contact between product and pumps or mechanical members. The filling level is adjustable: once selected, the machine automatically fills up the bottle to the desired level. Also, the tank from which the fluid is drawn can be placed even 4 meters below Enomaster and Enolmatic. Simple to use and clean: a great advantage especially when bottling oil. Several accessories are available in order to use Enomaster and Enolmatic also for filling mignon or out-of-standard bottles. Special nozzles and Special Kits have been specifically designed to fill bottles of any shape and size, including miniature bottles and demi-johns. Should the filling machine be employed for filling products with more than 20% alcohol content the pyrex recovery vessel is recommended (as well as the Tandem Professional pyrex filter-holder). The specially designed Tandem Filter can be combined with the Enolmatic, allowing the operator to filter and fill the product in the same operation, without external pumps but by mean of the vacuum created by Enolmatic.

Enomaster and Enolmatic Enomaster and Enolmatic filling machines operate like vacuum filler. It is the ideal equipment for edible juice and oil producers, cellars, wine-producers and distilleries. The ideal equipment for filling wine, oil, spirits, liquor, tomato sauce, fruit juices, and also liquids with relatively high viscosity. Through vacuum operated filling, the product is bottled in the most natural way, allowing to maintain the product original qualities and features. When placing the bottle under the machine, the fluid is drawn by the vacuum created inside the container itself, without any contact between product and pumps or mechanical members. The filling level is adjustable: once selected, the machine automatically fills up the bottle to the desired level. Also, the tank from which the fluid is drawn can be placed even 4 meters below Enomaster and Enolmatic. Simple to use and clean: a great advantage especially when bottling oil. Several accessories are available in order to use Enomaster and Enolmatic also for filling mignon or out-of-standard bottles. Special nozzles and Special Kits have been specifically designed to fill bottles of any shape and size, including miniature bottles and demi-johns. Should the filling machine be employed for filling products with more than 20% alcohol content the pyrex recovery vessel is recommended (as well as the Tandem Professional pyrex filter-holder). The specially designed Tandem Filter can be combined with the Enolmatic, allowing the operator to filter and fill the product in the same operation, without external pumps but by mean of the vacuum created by Enolmatic.

| EnolMatic | EnolMaster | |

| WINE about 250 bottles per hour | ||

| PRODUCTIVITY | OIL about 150 bottles per hour | OIL: about 500 bott/h (750ml bottles) |

| LIQUORS about 200 bottles per hour | WINE: about 600 bott/h (750ml bottles) | |

| DIMENSIONS | mm 200 x 400 x 400 | 650 x 460 x 450 mm |

| POWER | 120 W | |

| WEIGHT | kg. 4,00 | 25 Kg |

| ELECTRICAL SUPPLY | 220V – 50Hz | 220 V – 50/60 Hz |

| 110V – 60Hz | 100/110 v – 50/60 Hz | |

| BOTTLES FEATURES | ||

| NECK INTERNAL DIAMETER | From 16 mm up to 28 mm | from 16 up to 28mm |

| HEIGHT | From 250 mm up to 330 mm | from 250 up to 330mm |

Air-operated volumetric fillers manufactured with food grade materials. These machines are very light and easy to be moved and are available in different models. The product can be drawn from a container placed below the machine or from a storage tank without external pumps. These machines are particularly appreciated for oil filling because the product is bottled in the most natural way without to be shaken or mixed with air. These fillers are suitable for filling other liquid and semi-dense products in every kind of container and are excellent for filling tin cans with edible oil. The filling volume can be easily selected within a 200 to 5.000 ml range. Excellent performance also with non-food foamy products, such as detergents, shampoos, bubble bath liquids etc. In fact all the machine components in contact with the product can resist the attack of even aggressive chemical substances.

TECHNICAL FEATURES

DIMENSIONS: MM 490 X 490 X 1700 MM 490 X 650 X 1700

PRODUCTIVITY: ABOUT 800 LITRES/HOUR ABOUT 1.200 LITRES/HOUR

WEIGHT: KG 44 KG 80

OUTPUT RANGE: FROM 200 TO 5000 or 50 ML TO 2000 ML

CC SUPPLY: AIR COMPRESSED (6 BAR)

MATERIALS: METHACRYLATE, FOOD-GRADE POLYETHYLENE AND STAINLESS STEEL

CAPPING MACHINES

Semi-automatic machine with descending head for screwing aluminum PFP plugs with or without pourer (plastic for easier pouring). The bottle is placed in the machine by hand and a stopper is placed on the neck. By pressing two buttons on both sides of the base, the head lowers and closes the plug in seconds. Note that the machine is suitable for closing PFP plugs from a minimum of Ø 18 mm to a maximum of Ø 38 mm, but not Stelvin, BVS or MCA plugs. The 4-cylinder head, which only works when the cap is on the bottle, is made entirely of S / steel and adapted to close one size of cap.

Capacity: about 500/600 bottles / hour

Dimensions: 450 x 450 x 1100 mm

Weight: 50 kg

Power: 0.25 HP with V.T.S.

Voltage: 230V or 380 V

Corkers for cork, crown and plastic corks for sparkling wines with head

This is a robust, compact and easy-to-use machine. It is used for tamping different types of corks, synthetic taps, with diameter up to 25 mm and up to 45 mm in height, and with a crown cap and a plastic cap with a head even for plastic oil bottles.

These plugs are manually loaded into the machine, and then the bottle is placed. When you engage both start-button machine compacted the cork. Special head ensures perfect closure without damage to the surface of the cork.

This high-quality corker is equipped with condensate drip tray, regulator to adjust air pressure depending on the type of cork or stopper.

High quality components do not require lubrication.

Capacity: around 500/600 bottles / hour

Dimensions: mm 500 x 400 x 1000

Weight: 25 kg

Power: 0.25 / 0.5 HP (required compressed air)

Voltage: 230V or 380V on request

StarCap only for crown plugs

StarCap only for crown plugs

Pneumatic machine with descending head. 375 x 325 x 745 mm, 25 kg

Cap for crown plugs Ø 26, Ø 29

These are factory prices, on which transport costs in the amount of € 50-120 are calculated. Prices are subject to VAT.

CAPPING MACHINE FOR TOP i DOP CAPS